The history and legacy of the ground-breaking Ingalls Building in Cincinnati

My business interests require that I spend a lot of time in the United States with our stainless steel, PVD partners Kloeckner Metals Corporation at their Cincinnati plant in Ohio.

One recent weekend I was walking around Cincinnati’s Central Business District when I walked past a relatively non-descript and dilapidated office block. The building had a filthy brass commemorative plate bolted to it.

Brass plaque commemorating the Ingalls Building in Cincinatti, Ohio. Built in 1903, it was the first high-rise concrete frame building in the United States. Photograph by Charles Clark.

To my surprise, I realized that I had stumbled across the Ingalls Building – the first reinforced concrete high-rise structure in America. Before this remarkable building was constructed, the tallest concrete building in the entire world was only six stories high. Concrete is weak when subjected to pulling (tensile) forces and engineers feared a higher structure would risk collapsing under its own weight or wind loading.

Reinforced concrete construction

However, businessman Melville E. Ingalls and engineer Henry N. Hooper believed that, using the construction system patented in 1884 by the English engineer, Ernest Ransome, they could build much higher. Ransome’s method utilized casting concrete slabs around a cage of twisted steel bars, which allowed for floors, beams and joists all to be formed in concrete. This method also gave the building additional favourable properties such as excellent fire resistance and was a very rapid and economical construction method.

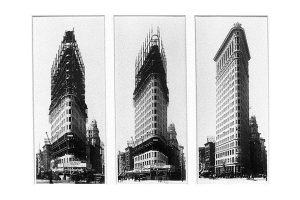

The Ingalls Building in Cincinatti,Ohio. The first concrete skyscraper in the United States, it was designated a National Historic Civil Engineering Landmark in 1973.

The plan was to use this new system of reinforcing concrete to build a sixteen-story office block and architects Elzner & Anderson were commissioned to design the ground-breaking, ‘skyscraper’. It took two years for Ingalls, the principal investor of the project, and Hooper to convince the city authorities, sceptical of this new construction method, to issue a building permit.

Construction of the Ingalls Building

Hooper decided that the structure of the building would be a monolithic concrete box, with the beams, floors, stairways and columns all made from reinforcing bar and concrete. All the reinforcing bar was interleaved and wired together so that the entire building was technically one piece and there was no need to use steel beams in the building.

The building took shape very quickly, and the construction team were able to produce three floors a month, working out to approximately 76 cubic meters of concrete per ten-hour shift.

The architects used the school of Beaux-Arts for the exterior design of the building and the first three floors of the concrete frame were clad in white marble. The floors from 4 to 15 were a resplendent grey glazed brickwork with the 16th floor, and the cornice above, all clad in terracotta that had been glazed white.

South-facing details of the upper floors and cornice of the Ingalls Building in Cincinatti. Designed by architects Elzner & Anderson at the turn of the 20th Century.

Photograph by Hhelvey.

The first concrete-frame skyscraper

On the day the building was completed and the supports were removed, one reporter sat up all night waiting for the building to collapse so that he could be the first to report on the disaster. Fortunately for all concerned the building confounded its doubters who could only stand and marvel at this structure soaring an unbelievable sixteen stories into the sky above the city.

Ingalls and Hooper’s success meant that reinforced concrete construction was gradually accepted as a solution for high rise construction, not only in the United States but the entire world. It is beautiful to think that all the stunning high rise concrete buildings around the world owe their existence to this neglected, old tower block in downtown Cincinnati.

The roof of the Sagrada Familia Basilica in Barcelona under construction. Concrete reinforced with steel bars is the method being used to erect this famous building.

Photograph by Etan J. Tal.

Reinforced concrete construction is now so successful that many of the world’s most famous buildings utilize this tried and trusted construction method. This includes the Sagrada Familia Basilica in Barcelona and the world’s tallest building, the Burj Khalifa in Dubai, which is an astonishing 828 metres tall.