Nitrogen (N) – part of a series on gases used during the physical vapour deposition (PVD) process – an innovative method for improving the performance of stainless steel

Nitrogen is a chemical element with an atomic weight of 14.00672. It sits on the periodic table between carbon and oxygen – atomic number 7.

The Earth contains enormous quantities of this element in its atmosphere. When we take a breath of air, standing at sea level, 99% percent of that breath is composed of only two elements, nitrogen (78%) and oxygen.

Current scientific theory is that the nitrogen in our atmosphere was vented from volcanic eruptions during the very early history of our planet.

An erupting volcano emitting a toxic cocktail of gases into the Earth’s atmosphere. The gases released include carbon dioxide, nitrogen and sulfur dioxide.

Discovery of nitrogen

The British botanist, physician and chemist Daniel Rutherford discovered nitrogen in 1772. After various experiments on mice, Rutherford found that the gas was unbreathable and an atmosphere composed of nitrogen could not sustain life. Rutherford also discovered that candles would not burn in an atmosphere high in nitrogen.

The French nobleman and chemist, Antoine Lavoisier, referred to the gas as ‘mephitic air’, meaning that it was noxious to humans. He suggested the newly discovered gas be named, ‘azote’, the Greek word for ‘no life’. However, the name never caught on in English as it was pointed out that all gases except for oxygen are mephitic to humans.

The English name ‘nitrogen’ was coined in 1790 by another Frenchman, Jean-Antoine Chaptal. He took the Latin words ‘nitre’ (potassium nitrate) and ‘gene’ (producing) and combined them to form nitrogen.

Nitrogen’s use in explosives

Nitrogen has had a checkered history since its discovery by Rutherford. We have used it to kill millions of people in wars as nitrogen and its chemical compounds are critical elements in gunpowder and high explosives.

A high explosive contains a tremendous amount of energy that can be released very quickly. To be classified as a high explosive, the explosive reaction must travel through the explosive material faster than the speed of sound.

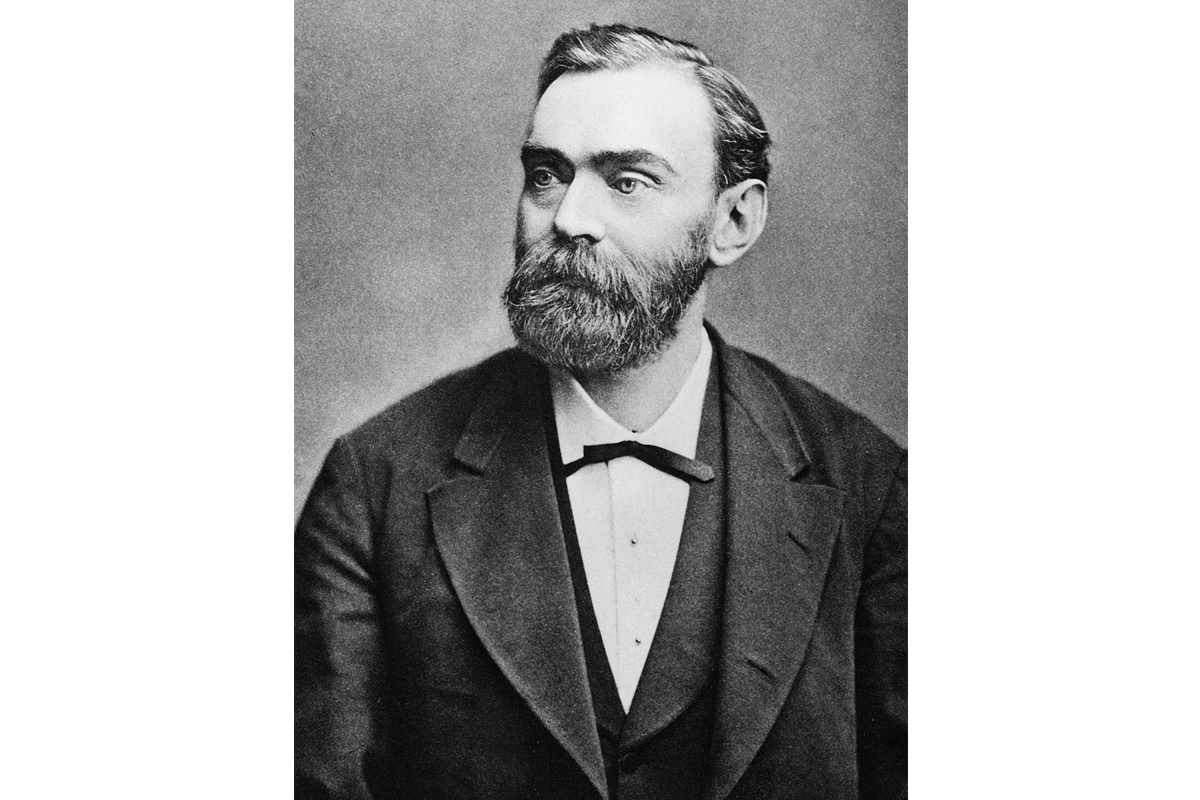

Handling highly explosive compounds like nitroglycerin is extremely dangerous and the Swedish scientist, Alfred Nobel, experimented with safer ways to do this after his younger brother Emil Nobel was killed in an explosion at the Nobels’ armaments factory in Heleneborg, Sweden in 1864.

Nobel found that when nitroglycerin was absorbed into an inert substance like diatomaceous earth it became safer to handle and easier to transport. He patented his invention in 1867 and called it ‘dynamite’. It was a huge success and along with his later invention of gelignite, afforded Nobel great financial wealth.

Photograph of Swedish scientist and philanthropist, Alfred Nobel (1833-96). Inventor of dynamite and gelignite, he left his fortune to the establishment of the Nobel Prizes.

In 1888, Alfred’s older brother Ludvig died, which led to a rather unfortunate mistake in several newspapers. They published obituaries about Alfred himself, rather than his dead brother.

In one French newspaper, the obituary contained the statement, ‘The merchant of death is dead’, referring to the many armaments factories Nobel had established as part of his business. Alfred was appalled by the thought that this is how he would be remembered and decided to set aside the bulk of his estate for the foundation of the Nobel Prizes. These were to be awarded each year for eminence in the sciences, literature and furtherance of world peace.

Industrial applications of nitrogen

Aside from the manufacture of armaments, nitrogen is a vital component in some products that have been highly beneficial to humanity. For example, most car airbags are made possible by a small, high explosive nitrogen substance called azine. This volatile compound, when detonated, will inflate an airbag in 25,000th of a second and in 2017, airbags had the distinction of saving 2,790 passenger lives in the USA alone.

However, nitrogen’s role in airbags pales completely into insignificance compared to the impact it has had in agriculture. In 1918, German chemist, Fritz Haber was awarded the Nobel Prize for Chemistry for the invention of the Haber-Bosch process that allowed the mass production of synthetic nitrogen fertilizer. The widespread use of these fertilizers has dramatically increased crop yields and been responsible for feeding billions of people and preventing starvation.

A farmer spraying fertilizer on his crops. The global, large-scale use of synthetic nitrogen fertilizers over the past century has completely transformed crop yields.

Today, it is estimated that at least one-third of the entire world’s population is fed directly because of the use of nitrogen-based fertilizers.

Nitrogen is also an element we use at Double Stone Steel in our environmentally friendly physical vapour deposition (PVD) process. We inject tiny quantities of nitrogen gas into our vacuum chambers to enable us to color stainless steel sheets and profiles for our customers.