Oxygen (O) – part of a series on gases used during the physical vapour deposition (PVD) process – an innovative method for improving the performance of stainless steel

Oxygen is everywhere, and we tend to think of it in its gaseous state – approximately 21% of the planet’s atmosphere is composed of oxygen. But did you know that oxygen also makes up as much of the Earth’s mass as iron? Iron and oxygen each comprise 32% of the planet we live on.

A satellite photograph of Earth. Oxygen is a major constituent of the planet’s mass and is the third most abundant element in the universe after hydrogen and helium.

Oxygen and the human body

Amazingly, as you sit reading this article on your computer, you are made up of approximately 65% oxygen. In fact, 96% of your body is made up of only six elements: oxygen 65%, carbon 18.5%, hydrogen 9.5%, nitrogen 3.2%, calcium 1.5% and phosphorus 1.0%. Therefore, a person weighing a modest 70 kilos, will contain 45.5 kilos of oxygen.

There are 94 naturally occurring elements found in nature and the human body contains an impressive 60 of those elements. Some of them have no known use in our bodies and some can be fatal to us in larger quantities like mercury, for example.

Discovery of oxygen

In 1772, the Swedish chemist Carl Scheele was successful in isolating the gas from air. Unfortunately, Scheele did not publish his results for another seven years and he was not credited as the discoverer. This late publishing of results became a habit with Scheele, earning him the nickname of “hard-luck Scheele” because he made a number of chemical discoveries before others without receiving the plaudits.

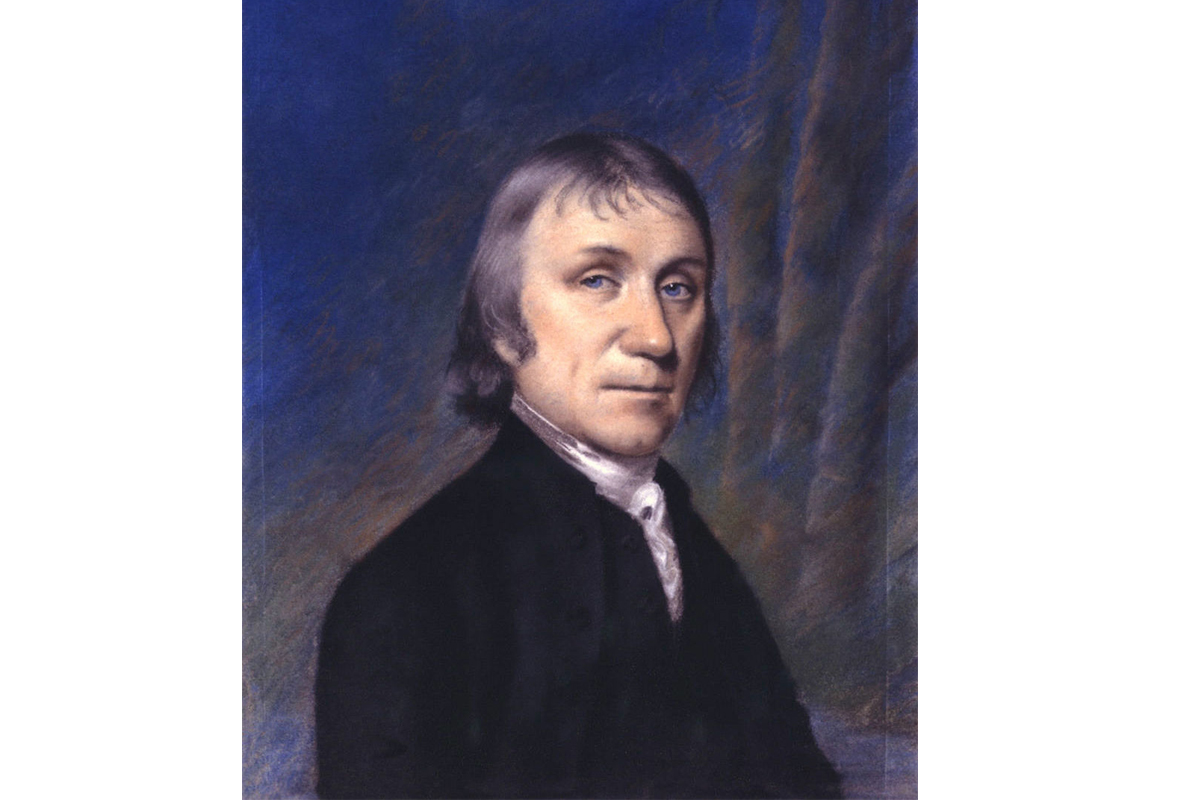

It was the British clergyman and chemist, Joseph Priestley, who was given recognition as the discoverer of oxygen. He published his findings in 1774 on how he had isolated the gas and called his discovery, ‘dephlogisticated air’. Phlogiston was thought to be a substance in all materials found on earth and oxygen was thought to be air that had this element removed. However, in reality ‘phlogiston’ did not exist.

Portrait of British scientist Joseph Priestley by Ellen Sharples (1769-1849). He is largely credited as the discoverer of oxygen having isolated the gas in 1774.

Renaming the gas

The French nobleman and chemist, Antoine Lavoisier, was opposed to the accepted phlogiston theory to which Priestley clung for the whole of his life. Priestley visited the French scientist shortly after his discovery and told him about his experiments and how he had liberated the new gas.

Lavoisier was intrigued by his English counterpart’s discovery but doubted the phlogiston theory and set about conducting his own quantitative experiments to discover if the new gas was in fact a chemical element. His research proved this to be the case, giving the first correct explanation of how combustion works in the process.

In 1777, Lavoisier renamed the gas ‘oxygen’, which means ‘acid-maker’ in Latin, as he mistakenly thought that oxygen was required to produce all acids. The new name gained in popularity and eventually entered the English language despite some resistance from English scientists loyal to Priestley and his original discovery.

Lavoisier later claimed to have discovered oxygen independently of Priestley but this was largely refuted by the scientific community and the aristocratic chemist later died on the guillotine in the aftermath of the French Revolution, charged with tax fraud.

Reactivity of oxygen

Oxygen is a very reactive element, and it will oxidise with most of the other elements. This natural oxidisation process is essential for stainless steel as it forms a thin protective coating on the surface of the metal. The layer is well adhered and does not flake off like rust.

A close-up shot of a marine-use stainless steel handrail. The metal is alloyed with chromium which reacts with oxygen to form a corrosion-resistant layer on the surface. Photograph by Southern Rigging Supplies.

This protective coating will stop the stainless steel from oxidising further and no more rust will form on the surface. If the protective oxidised layer gets scratched or damaged, it will immediately start to reform over the exposed area.

Oxygen is an essential element in the physical vapour deposition (PVD) process we use at Double Stone Steel. We inject tiny quantities of the gas into our vacuum chambers to enable us to color stainless steel sheets and profiles, anything from blue and green to more exotic pink, emerald and rainbow.