Chromium (Cr) – The discovery of chromium, its origins and wide-ranging industrial and aesthetic applications

Metals added to stainless steel include Chromium (Cr).

Chromium is an element – atomic number 24 – and it has an atomic weight of 51.9961. Chromium sits in the periodic table between the metals vanadium and manganese and possesses a beautiful and appealing color, being a mainly lustrous silvery-white.

Shown here are high purity chromium crystals and a polished chromium cube with very different textures but both demonstrating the characteristic lustrous silvery-white colour.

The origins of chromium

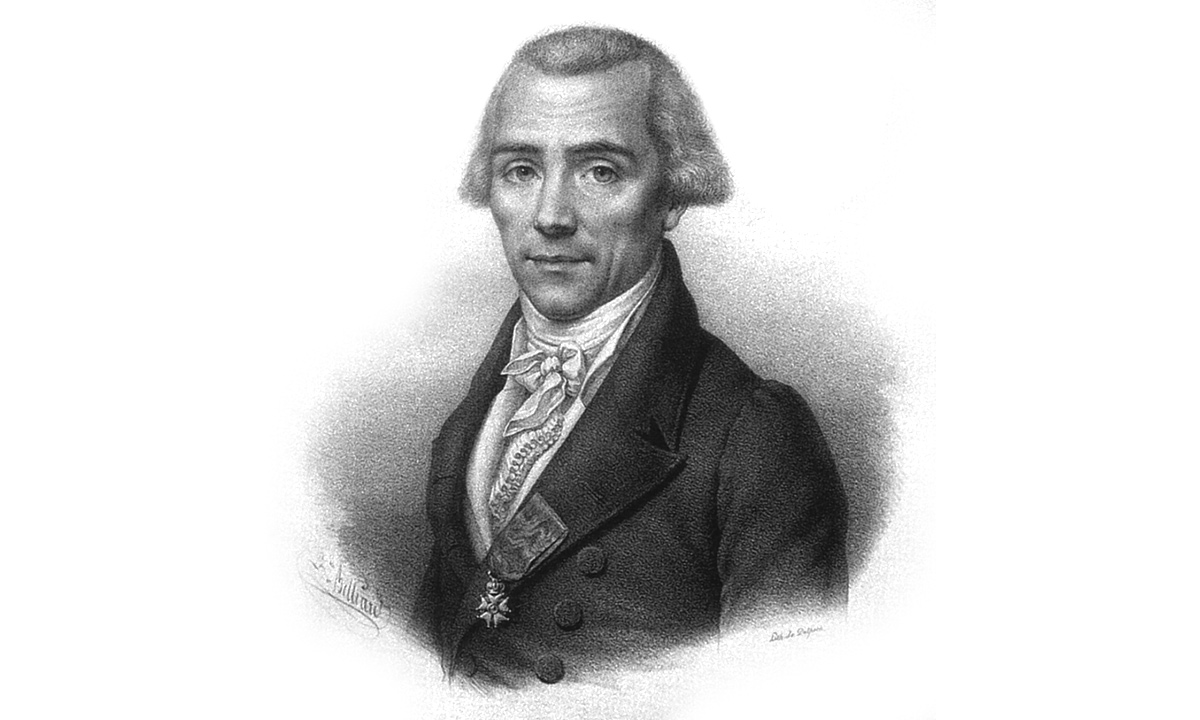

Chromium is a beautiful and useful element – the name comes from the Greek word for color, chroma. It was discovered in 1797 by the French scientist, Professor Nicolas Louis Vauquelin. Professor Vauquelin is held to be the father of modern metallurgy. He was born in Saint Andre d’Hebertot in May 1763 and passed away on the 14th November 1829 after a remarkably distinguished career, which included the discovery of a second element, the metal beryllium. Beryllium made nuclear weapons possible, so a little bit of a double-edged sword there.

Prof Louis Nicolas Vauquelin (16 May 1763 – 14 November 1829) was a French pharmacist and chemist. He was the discoverer of both chromium in 1797 and beryllium in 1798.

Prof Louis Nicolas Vauquelin (16 May 1763 – 14 November 1829) was a French pharmacist and chemist. He was the discoverer of both chromium in 1797 and beryllium in 1798.

Chromium in paint

Chromium ores were used extensively in the paint industry; for example, the pigment chrome yellow was very popular with artists and the paint industry. Chrome was an essential ingredient in the paint that was originally used to paint American school buses. These bright yellow buses are a part of American daily life.

The yellow school bus is an easily recognisable part of American culture and yellow paint derived from chromium ore was originally used to paint these buses.

However, paint manufacturers discovered that the yellow color they were applying was poisonous due to the heavy metals in it.

Chromite

It was recently estimated that there are 11 billion tonnes of minable chrome in the earth’s crust, making it the 21st most abundant element on the planet. That is not all the available chromium, that is the material we can reach using today’s technology.

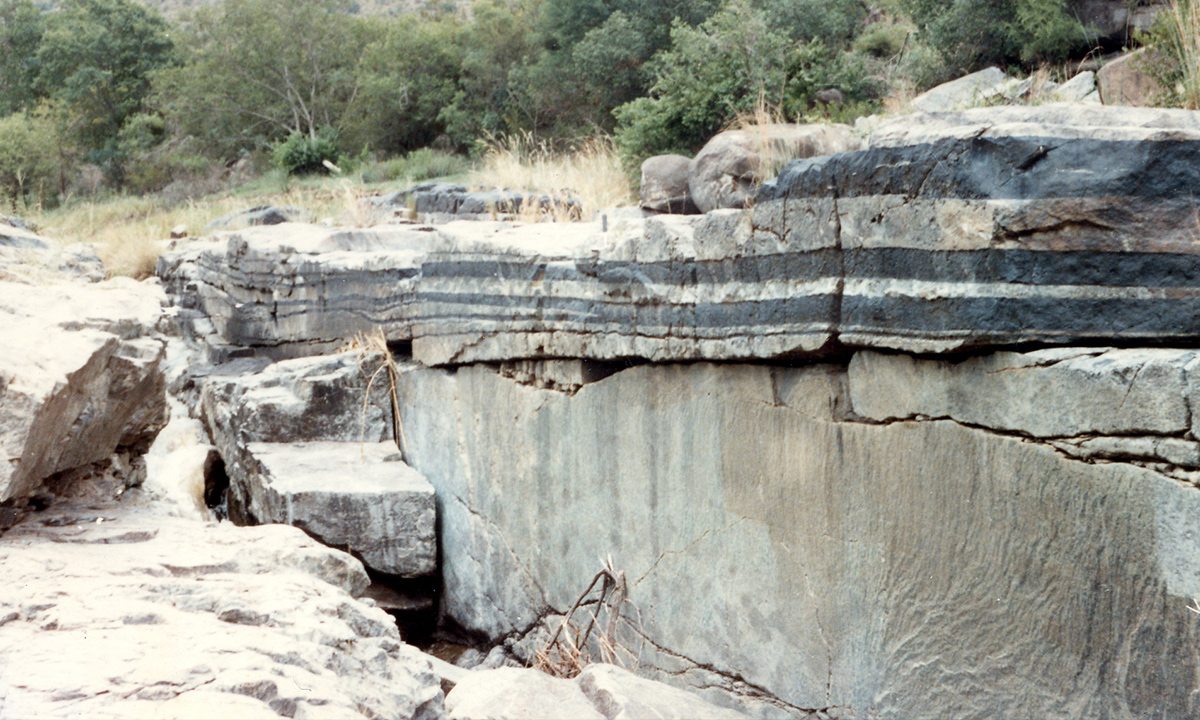

The most commercially important ore containing chromium is chromite. Chromite ore deposits have been uncovered in South Africa, Zimbabwe and Finland. Smaller but still precious chromite deposits are located in the USA, Russia and Greenland.

The vast Bushveld Igneous Complex of South Africa is a large layered mafic to ultramafic igneous body with some layers consisting of 90% chromite making the rare rock type, chromitite.

The vast Bushveld Igneous Complex of South Africa is a large layered mafic to ultramafic igneous body with some layers consisting of 90% chromite making the rare rock type, chromitite.

Chromium in humans

Chromium like lots of other elements is vital for human health. It is thought that chromium influences how insulin functions and the organ with the most amount of chromium in it is the placenta. The recommended daily intake for an adult human is between 25 and 35 micrograms per day – a tiny amount!

It is also critical for animals who, if denied all chromium in their diet, develop diabetes.

Industrial uses

One of chrome’s most essential roles in industry is that is can be alloyed with iron, nickel and other metals to produce stainless steel. Some stainless steels can contain up to 25% chrome in their formula.

Another well-known use for chrome is in the plating industry. For years, every car produced all over the world had many chromed parts fitted. From bumpers to door handles, a thick layer of lustrous chrome was considered to add value and visual appeal.

The process of applying a layer of chromium to steel, known as chrome plating, was used extensively in the car industry to add aesthetic appeal and durability. Photo credit: GmanViz

Unfortunately, chrome plating is considered by many to be an incredibly damaging process for the environment. This view is gaining ground because chrome plating uses many dangerous acids and chemicals that are very harmful to both people and to the environment. As a result, chrome plating is falling quickly out of favour in many countries and is likely to become a thing of the past in the next few years.

Alternatives to chrome plating

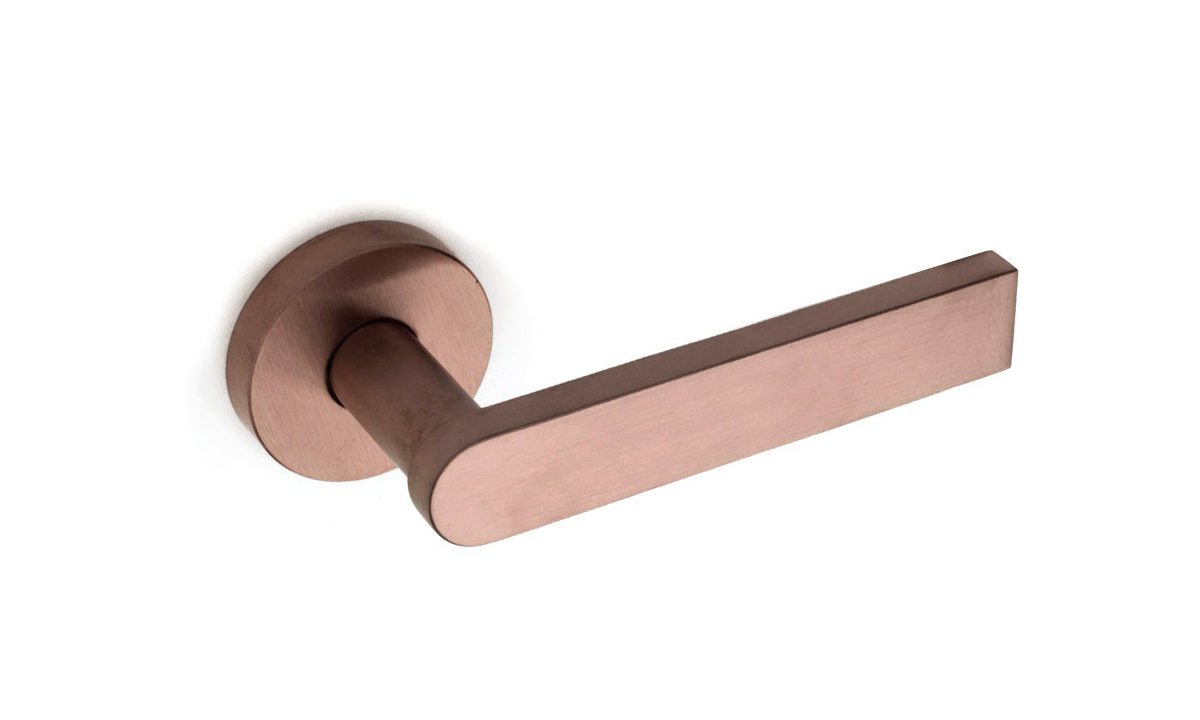

Apart from chrome vinyl wrapping the only other alternative to chrome is PVD (Physical Vapour Deposition) colored stainless steel. With the production of vinyl being notoriously full of dangerous chemicals this really only leaves PVD as the environmentally friendly option. The PVD process does not require acids or other harmful chemical solutions to be used, which means cleaning a PVD plant is minimal compared to cleaning a chrome plating plant. PVD does not produce a harmful waste product, unlike chrome plating, and the process itself does not produce harmful vapours.

To learn more on the PVD process read:- The basics of Physical Vapour Deposition by architect, Federico de Paoli

Lever handle in PVD coloured stainless steel. PVD is a more environmentally friendly alternative to chrome plating as it does not produce a toxic waste product.