The history of case-hardening and its processes

Describing the various processes of case-hardening.

Case-hardening is a metal surface process also referred to as surface hardening. It is an ancient technology that goes back to approximately 1400BC.

The origins of case-hardening

Around 1400 BC, hardening methods began to appear in armouries around the world. It was well known that the sharpness and hardness of a weapon’s edge could be enhanced by immediately plunging the newly formed weapon into cold water or oil after the item was heated up to the temperature required for forging. The temperate can also be judged by the color of the hot steel, you have to aim for a cherry red color.

It was known to make the edge harder and sharper, but it was not understood why the process made the edge better.

A tempered sword. Made of 5160 carbon steel the edge has been tempered slightly harder than a hammer.

Industrial processes

Case Hardening is a technique used to improve the durability and often the appearance of a metal surface in which the metal surface is reinforced by the adding of a thin layer at the top surface of another metal alloy. That thin layer of the alloy is generally much harder and durable than the original base metal.

2″ Case Hardened Steel Sheet Metal Screw with Pan Head Type and Zinc-Plated Finish, from Amazon.

Because the new hard surface completely surrounds the original item, literally encasing the object in a harder incasement it is known as Case Hardening.

Case Hardening steel is typically used to increase the lifespan of a particular product. This process is particularly beneficial to many types of product manufacturers from those that make gear cogs to those who manufacture firearms. Case Hardening is used on both carbon and alloy steels although usually mild steels are used.

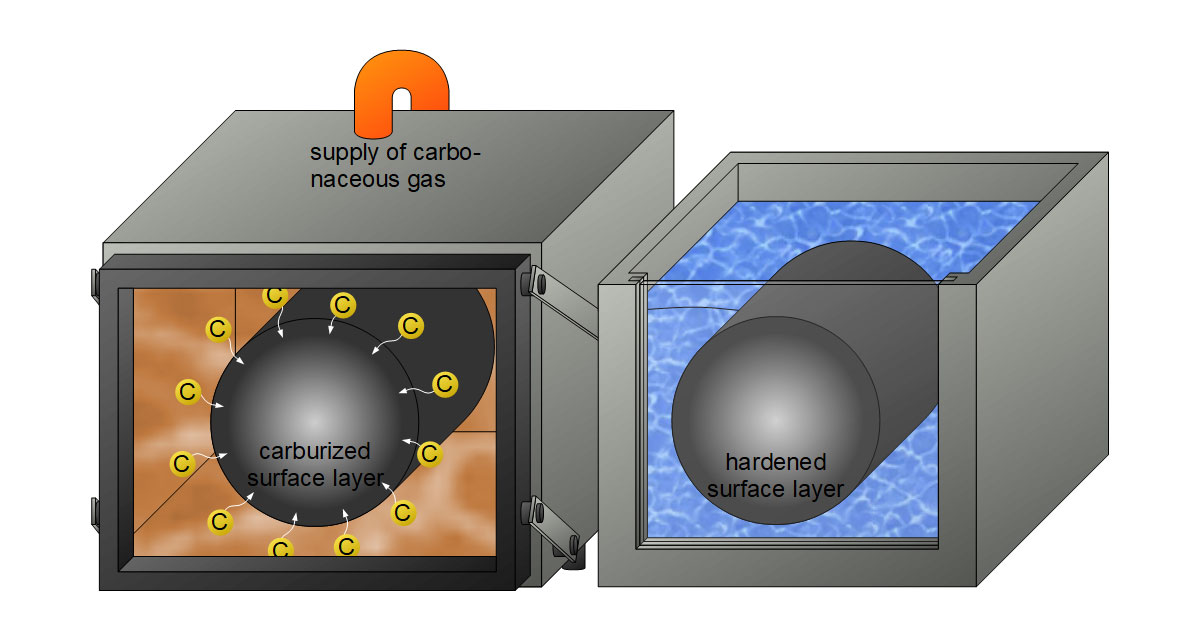

The Case Hardened steel is formed by diffusing carbon, nitrogen or boron into the outer layer of the steel’s surface at high temperature. The newly Case Hardened item can then be heat treated to give the surface layer the desired hardness.

As Case Hardening allows the product to have an extra tough top layer with a more flexible inner core, it is an excellent process for use on padlocks, and chain links and other security produces. The Case Hardening allows the product to resist cutting and the more flexible and less brittle core of the product will be better able to withstand impacts. Case Hardening is typically carried out after the product has been fully formed.

Diagram to show the process of Carburising Case Hardened Steel. Image courtesy of Tec-Science.

Case Hardening is suitable for many uses particularly in items that are repeatably impacted with other surfaces. So rifle bolts, firing pins and other mechanical parts that would typically be exposed to a harsh, wearing environments such as a camshaft in an internal combustion engine.

Using Carbon for Case Hardening

One version of Case Hardening, using carbon has the following method. Firstly the steel is heated while it is in contact with a substance that has a high carbon content. In the middle ages, the ironworker would use bone meal, horse hoofs and various other rather icky organic compounds that are naturally high in carbon.

Then the steel will be held at a relatively high temperature between 850c to 950 c for a prescribed period.

The hot steel will then be quenched quickly in a cold liquid such as water or oil, the quenching will produce the hardened surface layer, or as we have discussed, the Case Hardening.

The Case Hardened steel can then be tempered in an oven or using a direct heat source to the desired hardness. Tempering is carried out at around 190c. Tempering is a slow process taking place over hours.