Metals and Elements

The process of anodization and its early applications in aviation through to modern day consumer electronics

Richard Storer-Adam explains how metals are altered through anodizing and the anti-corrosive benefits and coloring options this process provides to product manufacturers.

The applications of Cor-Ten steel - from its beginnings in the US railroad industry to the worlds of art and architecture

Richard Storer-Adam runs through how this weathering steel alloy quickly moved beyond transport uses to give a distinct, rusted look to some iconic buildings and sculptures.

Nitrogen (N) - part of a series on gases used during the physical vapour deposition (PVD) process - an innovative method for improving the performance of stainless steel

Richard Storer-Adam investigates the paradoxical role nitrogen plays in both saving and destroying life as a critical element in the manufacture of explosives, agri-fertilisers and airbags.

Oxygen (O) - part of a series on gases used during the physical vapour deposition (PVD) process - an innovative method for improving the performance of stainless steel

Richard Storer-Adam explores the controversial discovery of oxygen, its importance to the human body and how it’s reactivity can be a vital component of metal manufacture.

Nickel (Ni) – part of a series on metals commonly alloyed with stainless steel to form varying grades of material.

Richard Storer-Adam looks into the origins of nickel, the part it plays in the composition of the planet and the industrial uses that make it a valuable metal alloy.

Chromium (Cr) – The discovery of chromium, its origins and wide-ranging industrial and aesthetic applications

Richard Storer-Adam continues a series on metals commonly alloyed with stainless steel to form varying grades of material.

Richard Storer-Adam is Managing Director of Double Stone Steel Ltd.

Titanium (Ti) – a brief history of the origins and commercial applications of titanium

Richard Storer-Adam begins a series on metals commonly alloyed with stainless steel to form varying grades of material.

The Acid Etching process on stainless steel and other metals.

An explanation of the truly ancient art of engraving, etching and intaglios on copper, mild steel, aluminium, brass and stainless steel by Richard Storer-Adam.

An introduction to hard-anodised aluminium coatings, their advantages and environmental implications for architectural cladding

An analysis of the color and corrosion properties of aluminium cladding, its maintenance and waste products.

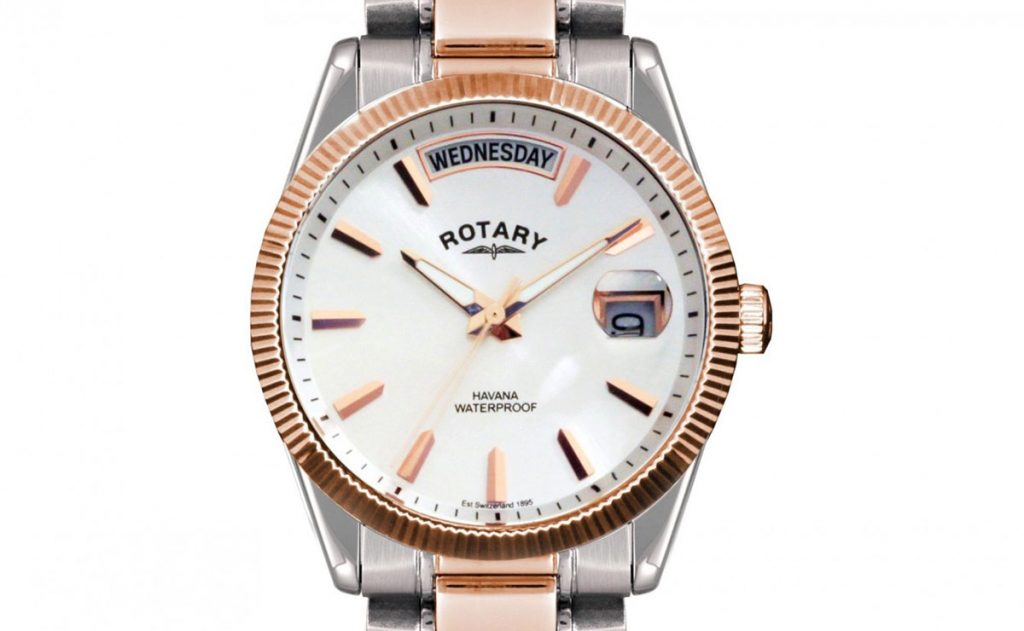

All that Glitters - a comparison between goldplating and gold PVD for jewellery

Richard Storer-Adam talks us through two different processes for creating the appearance of expensive, solid gold.

The history of case-hardening and its processes

Richard Storer-Adam gives the history of case hardening and describes the different processes of adding alloy to steel to create harder, sharper edges and surfaces.

Why and how do we electroplate? The transformation of goods made from base metals into higher-value commodities using precious metals

Richard Storer-Adam talks us through the process and weighs up the the aesthetic benefits and environmental disadvantages of electroplating.

The story of gold and gold leaf – how was gold formed, its decorative value and the 5000- year old process of gilding.

Richard Storer-Adam rounds up some interesting facts about how this fascinating metal has been used throughout history to coat other materials.

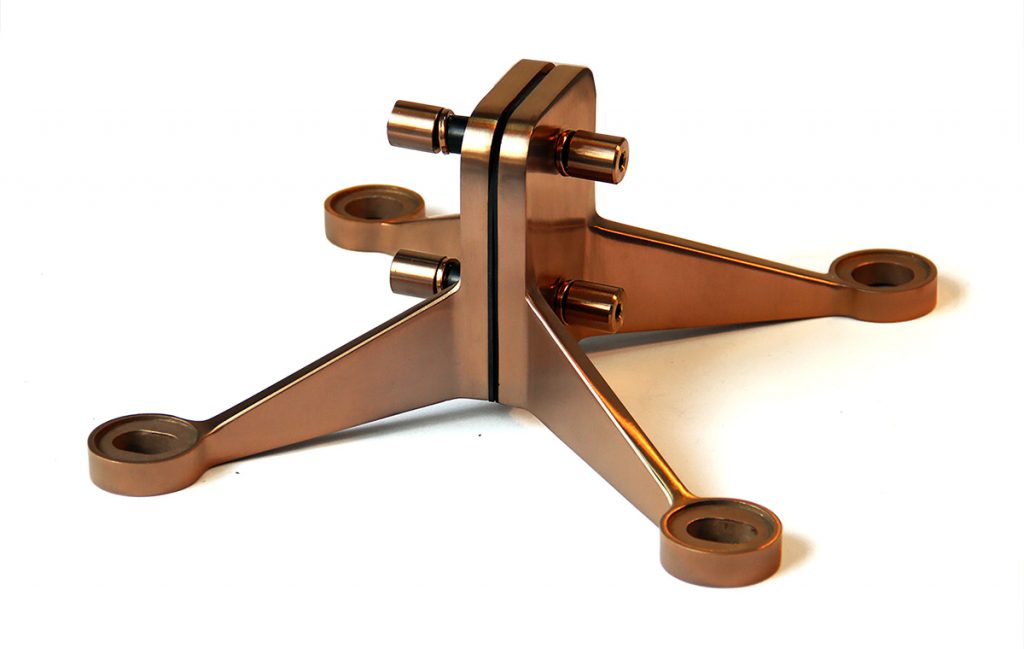

The basics of Physical Vapour Deposition

Imagine creating colored stainless steel was a cooking process - Federico de Paoli gives an explanation of the PVD process involving titanium, thermal evaporation, sputtering and ion-plating using comparisons from everyday life.