The story of gold and gold leaf – how was gold formed, its decorative value and the 5000- year old process of gilding.

A round up of some interesting facts about this fascinating metal.

In the beginning there was Gold

Gold is such a remarkable material, firstly it was created in the resultant blast of energy due to the collision of two neutron stars. This monumental collision produces enormous amounts of heavy elements including gold. The gold is expelled at tremendous speeds from these collisions and heads out into space. At some point in the very distant past, the gold was attracted to the Earth’s gravitational field and headed our way. When it got to our planet, the planet’s surface was molten and most of the gold sunk down, deep into the core of the Earth.

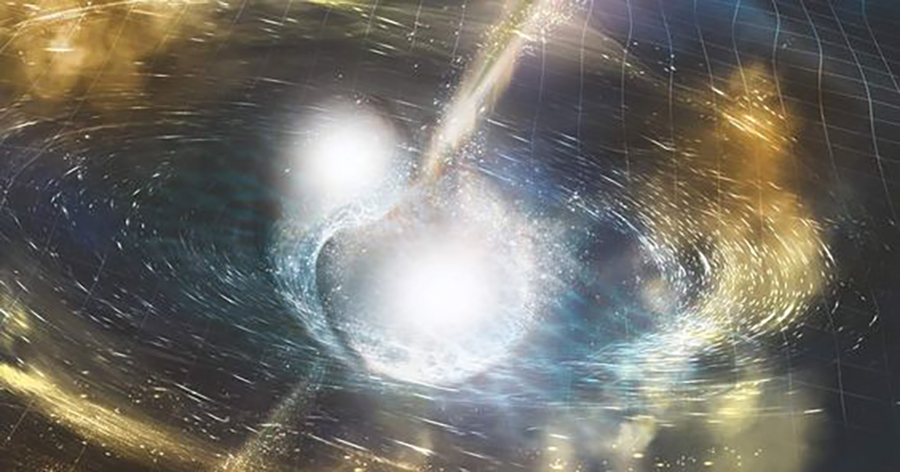

An artist’s impression of two neutron stars colliding and how they would appear as they merge, ejecting matter and gamma rays.

Image by NSF, LIGO, Sonoma State University, A. Simonnet

The nature and use of Gold

Gold is a soft metal that is extremely malleable and is in fact the most malleable metal found on earth. To define the term – ‘Malleable’, in regards to metals, this means that the metal can be formed or thinned by hammering or pressure without cracking or splitting. The word malleable has its roots in the Latin word ‘malleus’, which means ‘a hammer’.

Gold’s aesthetic properties has great appeal to many people involved with artistic applications and its malleability makes it much more accessible for many uses than solid gold. Transforming gold nuggets into gold leaf allows us to use less gold for decorative uses.

As a chemical element it bears the symbol AU and has a density of 19.3 g/cm3 making it the 6th densest metal on the planet.

Gold leaf detail on Corinthian bracket, upper detail of the pilaster, simple leaf spandrel, and French crown. By Monumental Plaster Moulding based in Maryland, US

Gold leaf

The exact date we as humans started using gold leaf is lost in the mists of time. Surprisingly making gold leaf is one of the oldest continuously used industrial or artistic process in human history.

Gold leaf is usually defined as a sheet of gold that will ordinarily vary from four to five-millionths of an inch in thickness (0.1 to 0.125 millionths of a meter or micrometres. To give an idea of how thin this is an individual strand of human hair can range in thickness from 1/1500 to 1/500 of an inch. So a human hair is much thicker than a sheet of gold leaf.

Gold leaf

A single gold nugget of approximately 10 millimetres in diameter can be beaten into a single fragile gold foil of about one square metre.

If you take a single avoirdupois ounce, this can be hammered into a sheet of approximately 300 square feet. Avoirdupois is an unusual word, it is a 15th-century English word which means ‘as sold by weight’, That English word, in its turn came from an old French phrase, ‘aveir de peis’, which literally ‘goods of weight.’

Egyptian Gold

Around 5,000 years ago, gold works and gold mines started to appear along the banks of the river Nile in Eygpt which is rich in gold. The purpose of these mines was to extract the gold ore found in the river.

Broad gold collar made in the reign of Thutmose III ca 1479 – 1425 BC. Made from Gold, Carnelian, Obsidian and Glass. Displayed at the Metropolitan Museum, Fifth Avenue. The necklace was a gift from King Thutmose to one of his three wives as indicated by the inscription of his name on the back of one of the falcon heads.

Egyptian metal workers discovered the extraordinary durability and the astounding malleability that pure gold possesses and became the world’s first gold beaters and gilders as depicted in tombs from that time. Their tools were basic however as these early masters of metals hammered their gold using a heavy, almost perfectly flat round stone to create the thinnest leaf possible using this method.

The technique has not changed much at all in all those 5000 years. Instead of using stones we now use metal hammers to work the gold into beaten sheets.

The application of gold leaf over a surface is called gold leafing or gilding and water gilding is the most skilled and challenging way to use gold leaf.

Gold leaf in space

Gold leaf has even found its way into the space industry. Gold leaf when beaten thin enough becomes transparent. Nasa uses this transparent gold leaf to cover the astronaut’s visors because of its excellent ability to reflect infrared light whilst allowing in visible light. The thin layer of gold protects astronauts’ eyes from the unfiltered sunlight.